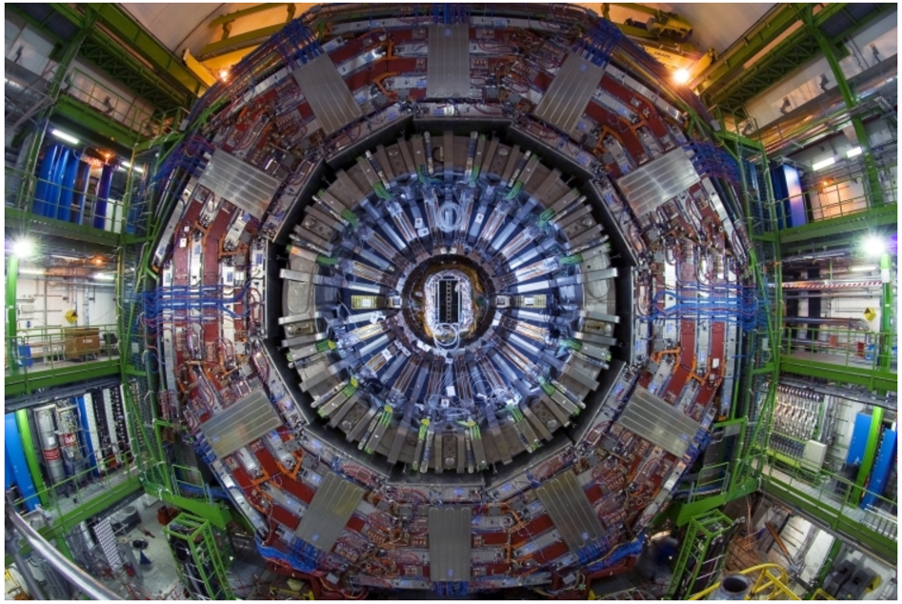

A fourth station –– called RE4 –– will be added to the CMS endcap muon system during the ongoing LHC Long Shutdown (LS1). The CMS muon system consists of three different sub-detectors: RPCs (Resistive Plate Chambers), DT (Drift Tubes) and CSC (Cathode Strip Chambers). The endcap region is made of CSCs and RPCs in the first three disks and RPCs will be installed in the fourth disk as part of the RE4 project. The construction of the RE4 is an international project carried out by teams from institutes in Belgium, Bulgaria, China, Colombia, Finland, Georgia, India, Italy, Korea, Mexico and Pakistan as well as from CERN. CERN plays an important role in the chamber construction and testing at the RPC laboratory located in building 904 at Prevessin where many physicists, engineers, technicians and students from around the world are working together. RE4 consists of 72 super-modules, each of which is made by two RPCs, for a total of 144 double-gap RPCs. These super-modules needed to be built and installed inside CMS within about 24 months. Nineteen institutions involved with the RPCs cover all the tasks and have been working very hard since the beginning of 2012, in order to complete the project by the end of 2014. These tasks are distributed among the following countries: Korea is responsible for the construction of 660 gas gaps and 10 chambers. Pakistan, Italy and Finland are working on the front-end electronics, DAQ and power system while India is producing and testing 200 cooling sets. Bulgaria, Mexico and Georgia are responsible for super-module assembly and testing. India, Italy and Pakistan are building the chamber services (gas, cooling and cabling). China provides the readout strips, mechanical frame boxes and participates in the chamber construction and testing at CERN. A large international team will work on the installation and commissioning of the full system. A total of 144 chambers will be assembled and tested at three different sites: CERN, Ghent (Belgium) and Mumbai (India). Work in Mumbai has been carried out jointly by a team from BARC and Panjab University. At these sites, quality control is performed on all other chamber components, which are then assembled in the chambers with an average speed of one chamber per day. After the construction, each chamber is tested in a cosmic stand for about a week in order to study the chamber performance and apply selection criteria. After a successful cosmic test, every chamber is powered on and monitored for about three weeks in order to check its stability over time. Afterwards, a pair of chambers is assembled into a super-module that is then sent to the CMS experimental site ready to be installed. So far, the three assembly sites have produced 72 RPC detectors, corresponding to 36 super-modules; these were installed earlier in December. The production for the second endcap disk started in September 2013 and should end at the beginning of 2014 in order to be ready for installation around mid-2014.

- Log in to post comments